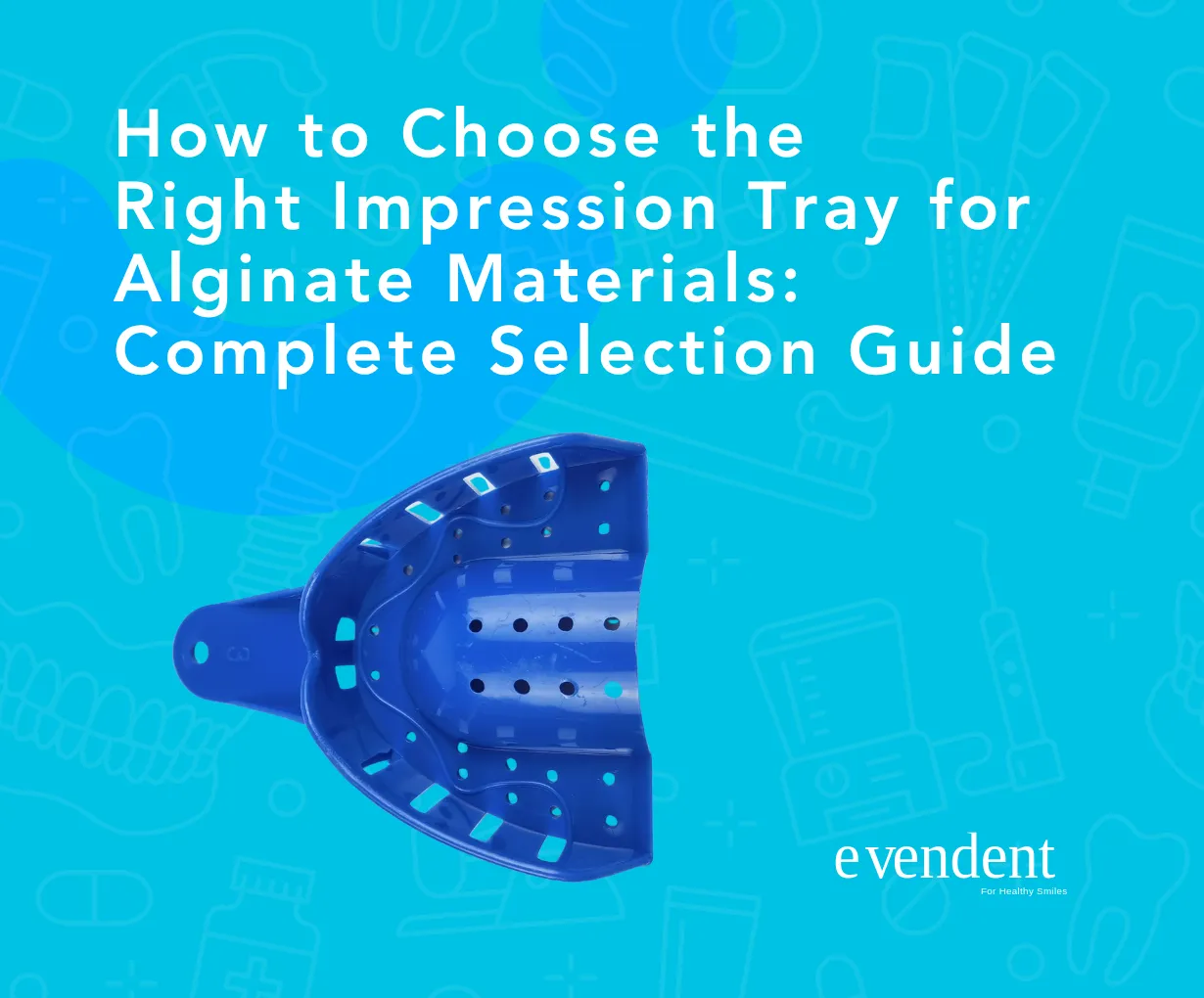

Selecting the appropriate impression tray is crucial for achieving accurate alginate impressions and optimal clinical results. The right tray ensures proper material distribution, adequate thickness, and comfortable patient positioning while maximizing the performance of your alginate impression materials. Understanding tray types, sizing principles, and material compatibility will significantly improve your impression quality and reduce remake rates.

Understanding Impression Tray Fundamentals

What Makes a Quality Impression Tray?

A quality impression tray serves as the foundation for successful alginate impressions, providing structural support and ensuring uniform material thickness. The tray must maintain dimensional stability under the pressure of setting alginate while allowing easy removal without distortion.

Key Functions:

- Material retention : Secure alginate during setting and removal

- Structural support : Prevent deformation under masticatory forces

- Uniform thickness : Ensure consistent 3-4mm alginate thickness

- Patient comfort : Minimize tissue trauma and discomfort

- Clinical efficiency : Streamline impression procedures

Essential Tray Components

Handle Design

- Ergonomic grip for secure control

- Positioned for optimal insertion angle

- Adequate length for comfortable manipulation

Rim Configuration

- Rounded edges to prevent soft tissue trauma

- Appropriate height for material retention

- Smooth surfaces for patient comfort

Perforation Pattern

- Strategic holes for mechanical retention

- Optimal size to prevent alginate extrusion

- Uniform distribution for consistent adhesion

Types of Impression Trays for Alginate Use

1. Metal Impression Trays

Advantages:

- Superior dimensional stability

- Autoclavable for repeated use

- Excellent alginate retention

- Cost-effective for high-volume practices

- Compatible with all alginate types

Disadvantages:

- Heavier weight during impression

- Potential for patient discomfort

- Higher initial investment

- Requires sterilization between uses

Best Applications:

- Routine diagnostic impressions

- Study model fabrication

- High-volume general practices

- Long-term cost considerations

2. Plastic Dental Impression Trays

Advantages:

- Lightweight and comfortable

- Disposable options available

- Transparent varieties for visibility

- Chemical resistance

- Lower per-use cost

Disadvantages:

- Limited dimensional stability

- Single-use environmental impact

- Potential for flexion under pressure

- Variable quality between manufacturers

Best Applications:

- Infection control protocols

- Pediatric dentistry

- Temporary or emergency procedures

- Practices prioritizing disposability

3. Plastic-Steel Dental Impression Tray

Advantages:

- Excellent mechanical retention

- Prevents alginate slippage

- Optimal material thickness control

- Professional appearance

- Suitable for complex cases

Disadvantages:

- Higher cost per unit

- Requires proper loading technique

- May need adhesive backup

- Limited size variations

Best Applications:

- Precision prosthetic work

- Complex jaw relationships

- Quality-focused practices

- Challenging anatomical cases

4. Perforated vs. Non-Perforated Trays

Perforated Trays:

- ✅ Superior mechanical retention

- ✅ Reduced alginate slippage

- ✅ Better material adhesion

- ✅ Suitable for all alginate types

- ❌ More difficult to clean (reusable types)

Non-Perforated Trays:

- ✅ Easier cleaning and sterilization

- ✅ Smoother tissue contact

- ✅ Better for adhesive systems

- ❌ Requires tray adhesive

- ❌ Higher risk of material separation

Tray Sizing and Selection Criteria

Anatomical Considerations

Maxillary Tray Selection:

- Arch width : 2-3mm wider than widest point

- Arch length : Extends 2-3mm beyond last tooth

- Palatal coverage : Complete palatal surface

- Tissue clearance : 3-4mm for adequate alginate thickness

Mandibular Tray Selection:

- Arch width : Accommodates widest buccal surfaces

- Arch length : Extends beyond retromolar pads

- Lingual clearance : Adequate space for tongue comfort

- Floor coverage : Complete vestibular extension

Standard Sizing Guidelines

Small Trays:

- Maxillary : 45-50mm arch width

- Mandibular : 40-45mm arch width

- Applications : Pediatric patients, narrow arches

- Age range : Children 6-12 years typically

Medium Trays:

- Maxillary : 50-55mm arch width

- Mandibular : 45-50mm arch width

- Applications : Average adult patients

- Most common : 70-80% of adult population

Large Trays:

- Maxillary : 55-60mm arch width

- Mandibular : 50-55mm arch width

- Applications : Broad arches, large patients

- Considerations : Ensure patient comfort

Special Sizing Considerations

Edentulous Patients:

- Require different tray proportions

- Focus on denture-bearing areas

- Consider ridge resorption patterns

- May need custom tray fabrication

Pediatric Patients:

- Smaller tray dimensions

- Comfortable handle positioning

- Rounded edges essential

- Consider behavioral factors

Orthodontic Cases:

- Accommodate bracket clearance

- Consider arch expansion

- Plan for appliance interference

- May require modified trays

Material Compatibility with Alginate Types

EvenDent Alginate Compatibility

Universal Type Alginate (E50001):

- Ideal trays : Perforated metal or plastic

- Thickness requirement : 3-4mm uniform

- Retention : Mechanical (perforations) or adhesive

- Setting time : 3-minute accommodation needed

High Precision Type Alginate (E50002):

- Ideal trays : Metal with fine perforations

- Precision requirements : Dimensional stability crucial

- Thickness control : Consistent 3-4mm critical

- Applications : Crown and bridge impressions

Super High Precision Type Alginate (E50003):

- Ideal trays : High-quality metal rim-lock

- Precision demands : Maximum dimensional accuracy

- Quality considerations : Professional-grade trays only

- Applications : Complex prosthetic cases

Tray Adhesive Considerations

When to Use Adhesive:

- Non-perforated trays

- Smooth plastic surfaces

- Critical accuracy requirements

- Difficult anatomical cases

Application Technique:

- Thin, uniform coating

- Allow proper drying time

- Avoid pooling in tray

- Compatible with alginate chemistry

Step-by-Step Tray Selection Process

1. Patient Assessment

Measure Arch Dimensions:

- Use flexible measuring tape

- Record widest buccal width

- Measure anterior-posterior length

- Note any anatomical variations

Evaluate Oral Anatomy:

- Assess vestibular depth

- Check for tori or exostoses

- Identify limited opening

- Consider gag reflex sensitivity

2. Tray Trial and Verification

Fit Assessment:

- Anterior clearance : 2-3mm beyond incisors

- Posterior extension : Past last molars

- Lateral clearance : 2-3mm beyond buccal surfaces

- Tissue clearance : 3-4mm for alginate thickness

Comfort Evaluation:

- No tissue blanching

- Comfortable insertion and removal

- Adequate breathing space

- No pressure points

3. Final Selection Criteria

Priority Factors:

- Patient comfort : Primary consideration

- Alginate thickness : Uniform 3-4mm

- Retention adequacy : Mechanical or adhesive

- Clinical efficiency : Streamlined workflow

- Cost-effectiveness : Practice economics

Tray Preparation and Loading Techniques

Pre-Impression Preparation

Tray Inspection:

- Check for cracks or damage

- Verify proper size selection

- Ensure clean, dry surfaces

- Apply adhesive if required

Patient Positioning:

- Upright, comfortable position

- Head support adequate

- Breathing instructions clear

- Evacuation system ready

Optimal Loading Technique

Alginate Distribution:

- Posterior loading : Fill posterior regions first

- Anterior placement : Smooth anterior coverage

- Excess material : Slight overflow acceptable

- Air bubble prevention : Gentle placement technique

Loading Sequence:

- Mix alginate : Following manufacturer’s ratio (10g:22mL for EvenDent)

- Load posterior : Fill deepest areas first

- Smooth anterior : Even distribution

- Check thickness : Ensure adequate material

- Immediate insertion : Within working time

Insertion and Positioning

Insertion Technique:

- Approach angle : Slightly posterior first

- Gentle pressure : Avoid tissue trauma

- Centering : Ensure midline alignment

- Seating : Complete, even pressure

Holding Position:

- Stable grip : Secure tray handle

- Patient guidance : Breathing instructions

- Timing : Monitor chromatic color change

- Removal preparation : Steady, controlled motion

Troubleshooting Common Tray Issues

Problem: Alginate Separation from Tray

Causes:

- Inadequate mechanical retention

- Missing or insufficient adhesive

- Tray surface contamination

- Premature tray removal

Solutions:

- Use perforated trays for mechanical retention

- Apply proper tray adhesive technique

- Ensure clean, dry tray surfaces

- Wait for complete alginate setting (3 minutes)

Problem: Inadequate Alginate Thickness

Causes:

- Oversized tray selection

- Insufficient material loading

- Improper tray positioning

- Patient movement during setting

Solutions:

- Select properly sized tray (3-4mm clearance)

- Load adequate alginate volume

- Ensure proper tray seating

- Provide clear patient instructions

Problem: Distorted Impressions

Causes:

- Tray flexion during setting

- Inadequate dimensional stability

- Improper removal technique

- Patient movement

Solutions:

- Use rigid, high-quality trays

- Ensure proper tray selection

- Train proper removal technique

- Improve patient communication

Problem: Patient Discomfort

Causes:

- Oversized tray selection

- Sharp or rough tray edges

- Excessive insertion pressure

- Inadequate patient preparation

Solutions:

- Select appropriate tray size

- Inspect tray edges for smoothness

- Use gentle insertion technique

- Provide thorough patient education

Cost-Effectiveness Analysis

Disposable vs. Reusable Trays

Disposable Plastic Trays:

- Cost per use : $0.50-1.50

- Advantages : No sterilization, infection control

- Disadvantages : Environmental impact, ongoing cost

- Best for : High-volume practices, infection control priorities

Reusable Metal Trays:

- Initial investment : $15-30 per tray

- Cost per use : $0.05-0.15 (including sterilization)

- Advantages : Long-term economy, superior quality

- Disadvantages : Sterilization time, initial cost

- Best for : Quality-focused practices, long-term economics

Total Cost of Ownership

Factors to Consider:

- Tray purchase cost : Initial investment

- Sterilization costs : Time and materials

- Replacement frequency : Durability factors

- Remake rates : Quality impact on clinical outcomes

- Staff time : Efficiency considerations

ROI Optimization

High-Volume Practices:

- Consider reusable metal trays

- Invest in quality for durability

- Calculate break-even point

- Factor in remake reduction

Quality-Focused Practices:

- Prioritize dimensional stability

- Consider rim-lock designs

- Invest in precision tools

- Monitor accuracy outcomes

Selection Recommendations by Practice Type

General Dental Practice

Recommended Setup:

- Metal perforated trays : 3 sizes each arch

- Plastic disposable backup : For infection control

- Tray adhesive : For non-perforated applications

- Sterilization system : Efficient turnover

Rationale:

- Cost-effective long-term solution

- Excellent alginate retention

- Suitable for routine impressions

- Balanced quality and economics

Prosthodontic Practice

Recommended Setup:

- High-quality metal rim-lock trays : Multiple sizes

- Precision perforated trays : For accuracy

- Custom tray materials : For complex cases

- Quality adhesive systems : Professional grade

Rationale:

- Maximum dimensional accuracy

- Superior alginate retention

- Professional appearance

- Precision requirements

Orthodontic Practice

Recommended Setup:

- Perforated metal trays : Bracket clearance

- Pediatric sizes : Complete range

- Comfortable handles : Patient-friendly design

- Efficient workflow : High-volume considerations

Rationale:

- Accommodate orthodontic appliances

- Pediatric patient comfort

- High-volume efficiency

- Study model accuracy

Pediatric Dental Practice

Recommended Setup:

- Small perforated trays : Complete size range

- Comfortable designs : Rounded edges

- Bright colors : Patient engagement

- Disposable options : Infection control

Rationale:

- Child-specific sizing

- Comfort and safety priorities

- Behavioral considerations

- Infection control needs

Quality Assurance and Maintenance

Tray Inspection Protocol

Daily Checks:

- Visual inspection for cracks

- Handle stability verification

- Perforation integrity

- Edge smoothness assessment

Weekly Maintenance:

- Deep cleaning procedures

- Sterilization effectiveness

- Dimension verification

- Replacement planning

Sterilization Best Practices

Autoclave Protocols:

- Temperature : 121°C (250°F)

- Time : 15-20 minutes

- Pressure : 15 psi

- Drying : Complete cycle

Chemical Sterilization:

- Glutaraldehyde : 2-4% solution

- Immersion time : 10-12 hours

- Rinsing : Thorough with sterile water

- Drying : Sterile environment

Replacement Indicators

When to Replace:

- Visible cracks or damage

- Perforation enlargement

- Handle loosening

- Dimensional changes

- Excessive wear patterns

Integration with Digital Workflows

Hybrid Approaches

Digital-Physical Integration:

- Physical impressions for accuracy

- Digital scanning for verification

- Model fabrication optimization

- Workflow efficiency

Benefits:

- Quality assurance

- Reduced remakes

- Enhanced accuracy

- Future-ready protocols

Transition Considerations

Gradual Implementation:

- Maintain alginate capabilities

- Selective digital adoption

- Staff training priorities

- Economic considerations

Future Trends in Impression Tray Technology

Material Innovations

Advanced Plastics:

- Improved dimensional stability

- Enhanced biocompatibility

- Reduced environmental impact

- Cost-effective manufacturing

Smart Materials:

- Temperature-responsive components

- Integrated timing indicators

- Comfort-optimized designs

- Patient-specific adaptations

Design Evolution

Ergonomic Improvements:

- Enhanced patient comfort

- Improved practitioner control

- Reduced fatigue factors

- Universal sizing approaches

Sustainability Focus:

- Biodegradable materials

- Reusable designs

- Reduced packaging waste

- Environmental responsibility

Conclusion and Best Practices

Selecting the right impression tray is fundamental to achieving consistent, high-quality alginate impressions. The ideal tray provides adequate material space, secure retention, and patient comfort while supporting the specific characteristics of your chosen alginate material.

Key Selection Principles:

- Size appropriately : 3-4mm clearance for optimal alginate thickness

- Prioritize retention : Perforated trays or quality adhesive systems

- Consider practice type : Match tray selection to clinical needs

- Invest in quality : Superior trays improve outcomes and reduce costs

- Maintain properly : Regular inspection and sterilization protocols

Success Factors:

- Proper patient assessment and measurement

- Appropriate tray trial and verification

- Correct alginate loading techniques

- Gentle insertion and positioning

- Complete setting time adherence

Economic Considerations:

- Balance initial cost with long-term value

- Calculate true cost per use including sterilization

- Factor in remake rates and quality outcomes

- Consider practice volume and workflow efficiency

By following these guidelines and selecting appropriate impression trays, dental professionals can maximize the performance of their alginate impression materials while ensuring patient comfort and clinical efficiency.

Optimize Your Impression Results with Quality Trays

Ready to improve your alginate impression accuracy and efficiency? The right impression tray is essential for maximizing the performance of your alginate materials and achieving consistent clinical results.

Why Professional Tray Selection Matters

✅ Improved Accuracy – Proper tray selection ensures optimal alginate thickness and dimensional stability

✅ Enhanced Retention – Quality trays prevent alginate separation and impression distortion

✅ Patient Comfort – Appropriate sizing and design reduce discomfort and improve cooperation

✅ Clinical Efficiency – Streamlined workflows and reduced remake rates

✅ Cost-Effectiveness – Lower long-term costs through quality outcomes and durability

Tray Recommendations for EvenDent Alginate Materials

For Universal Type Alginate (E50001):

- Metal perforated trays for routine impressions

- Standard sizing with 3-4mm clearance

- Cost-effective solutions for general practice

For High Precision Type Alginate (E50002):

- Quality metal trays with fine perforations

- Dimensional stability for crown and bridge work

- Professional-grade retention systems

For Super High Precision Type Alginate (E50003):

- Premium rim-lock or high-quality metal trays

- Maximum dimensional accuracy for complex cases

- Investment-grade tools for specialist practices

Complete Impression Solution

Combine EvenDent chromatic alginate materials with quality impression trays for optimal results:

- 20μm particle fineness for exceptional detail

- Color-change indicators for perfect timing

- Three precision levels for every application

- Dust-free formula for cleaner procedures

Get Expert Guidance

🌐 Visit our website : evendent.com

📧 Technical consultation : Product selection and clinical guidance available

📦 Sample requests : Try our alginate materials with your preferred trays

Shanghai Even Medical Instruments Co., Ltd

Expert Support : Comprehensive clinical training and product education

Quality Assurance : ISO certified manufacturing with rigorous testing

Global Service : International shipping and technical support

Professional Partnership : Dedicated to your clinical success

Maximize your alginate impression results with the right combination of quality materials and professional trays. Contact EvenDent today for personalized product recommendations and clinical guidance.

Continue Reading: