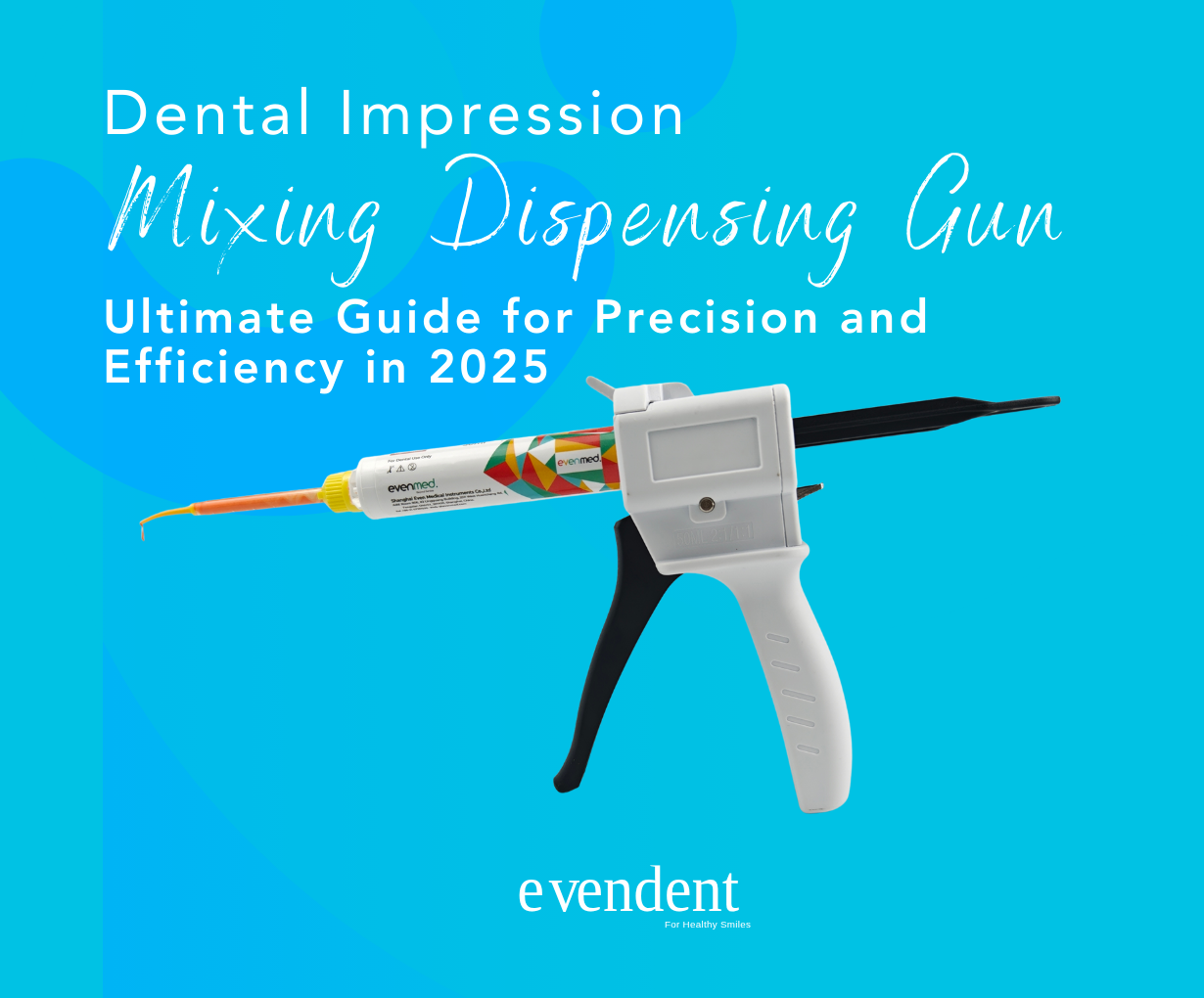

The dental impression mixing dispensing gun has revolutionized how modern dental practices handle impression materials, transforming a once tedious manual process into a precise, efficient procedure. Whether you’re a seasoned dentist looking to upgrade your equipment or a dental technician seeking to improve workflow efficiency, understanding the intricacies of these essential tools can significantly impact your practice’s success. This comprehensive guide explores everything from selection criteria to advanced techniques, helping you maximize both clinical outcomes and return on investment.

Understanding Dental Impression Mixing Dispensing Guns

What Makes Modern Dispensing Guns Essential?

The evolution from manual mixing to automated impression dispensing systems represents one of the most significant advancements in dental materials handling. Today’s dental mixing guns offer unprecedented precision, consistency, and time savings that directly translate to better patient outcomes and increased practice profitability.

Modern impression material dispensers utilize sophisticated mechanical ratios to ensure perfect mixing every time. Unlike traditional hand mixing methods that often result in air bubbles, inconsistent ratios, or material waste, these devices deliver homogeneous mixtures with optimal working properties.

Key Components and Mechanisms

The auto-mixing impression gun consists of several critical components working in harmony:

- Dual-barrel cartridge system : Accommodates base and catalyst materials

- Plunger mechanism : Provides controlled, consistent pressure

- Mixing tips : Ensure thorough blending through static mixing elements

- Trigger mechanism : Offers precise flow control

- Release lever : Prevents material waste between applications

Understanding these components helps practitioners troubleshoot issues and maintain optimal performance throughout the device’s lifespan.

Types of Impression Dispensing Guns and Their Applications

Manual vs. Electric Dispensing Systems

The dental dispensing system market offers two primary categories, each with distinct advantages:

Manual Dispensing Guns:

- Cost-effective initial investment

- No power requirements

- Lightweight and portable

- Ideal for low-volume practices

- Requires more physical effort

Electric Dispensing Guns:

- Consistent flow rate

- Reduced hand fatigue

- Higher precision control

- Better for high-volume practices

- Higher initial investment

Specialized Systems for Different Materials

Different impression materials require specific mixing tip systems and dispensing ratios:

- Polyvinyl Siloxane (PVS) Systems : Require 1:1 or 10:1 mixing ratios

- Polyether Systems : Typically use 1:1 ratios with specialized tips

- Alginate Substitute Systems : Need specific cartridge configurations

- Bite Registration Materials : Utilize smaller, more precise tips

Selection Criteria for Your Practice

Evaluating Your Clinical Needs

Choosing the right impression accuracy tools involves careful consideration of multiple factors:

Practice Volume Considerations:

- Daily impression procedures performed

- Types of restorations commonly fabricated

- Staff size and skill levels

- Budget constraints

Material Compatibility:

- Verify gun compatibility with preferred impression materials

- Consider future material adoption possibilities

- Evaluate mixing tip availability and costs

Cost-Benefit Analysis

When investing in dental efficiency equipment, consider both immediate and long-term factors:

Initial Investment:

- Gun purchase price

- Training requirements

- Compatible material costs

- Mixing tip inventory

Long-term Savings:

- Reduced material waste (typically 15-20% savings)

- Decreased chair time

- Improved remake rates

- Enhanced patient satisfaction

Best Practices for Optimal Performance

Proper Loading and Preparation Techniques

Maximizing your impression gun maintenance starts with proper loading procedures:

- Inspect cartridge integrity before loading

- Remove air bubbles by expressing small amount of material

- Attach mixing tip firmly with quarter-turn lock

- Prime the system with 1-2 trigger pulls

- Check flow consistency before patient application

Clinical Application Guidelines

Achieving consistent results requires attention to technique:

Temperature Considerations:

- Store materials at room temperature (68-72°F)

- Allow refrigerated materials to equilibrate

- Consider seasonal temperature variations

Application Speed:

- Maintain steady, consistent pressure

- Avoid stopping mid-impression

- Complete full-arch impressions within working time

Troubleshooting Common Issues

Even the best dental mixing gun can encounter problems. Here’s how to address them:

Uneven Flow:

- Check for clogged mixing tips

- Verify cartridge expiration dates

- Inspect plunger alignment

Material Setting Too Quickly:

- Replace mixing tips between patients

- Verify proper storage conditions

- Check material batch consistency

Maintenance and Longevity

Daily Care Protocols

Proper impression dispensing gun maintenance ensures years of reliable service:

After Each Use:

- Remove mixing tip immediately

- Wipe external surfaces with approved disinfectant

- Inspect moving parts for material buildup

- Store in designated area

Weekly Maintenance:

- Disassemble according to manufacturer guidelines

- Clean all accessible components

- Lubricate moving parts if recommended

- Test trigger mechanism smoothness

When to Replace Your Equipment

Signs indicating replacement consideration:

- Inconsistent material flow despite maintenance

- Excessive trigger resistance

- Visible wear on critical components

- Frequent mixing tip detachment

- Outdated compatibility with new materials

Advanced Techniques and Innovations

Digital Integration Possibilities

Modern dental practices increasingly integrate impression accuracy tools with digital workflows:

- QR code scanning for material tracking

- Automatic usage documentation

- Integration with practice management software

- Predictive maintenance alerts

Emerging Technologies

The future of dental dispensing systems includes:

Smart Dispensing Features:

- Pressure sensors for consistency monitoring

- Bluetooth connectivity for data collection

- LED indicators for material status

- Automated mixing ratio adjustments

[Image Position 5: Future technology concept illustration]

Frequently Asked Questions

How often should mixing tips be replaced?

Mixing tips should be replaced after each patient use to ensure optimal mixing quality and prevent cross-contamination. Never attempt to clean and reuse tips, as this compromises material properties and infection control protocols.

Can one gun work with multiple material brands?

While many impression dispensing guns offer universal compatibility, always verify specific brand requirements. Some manufacturers design proprietary systems that may limit material options but optimize performance.

What’s the average lifespan of a quality dispensing gun?

A well-maintained dental mixing gun typically lasts 5-7 years with regular use. Electric models may require motor replacement after 3-4 years, while manual guns often exceed this timeframe with proper care.

How do I calculate the ROI on a dispensing gun investment?

Calculate material savings (typically 15-20%), reduced chair time (5-10 minutes per procedure), decreased remake rates, and staff efficiency improvements. Most practices recover investment within 6-12 months.

Maximizing Your Investment

The dental impression mixing dispensing gun represents more than just equipment—it’s an investment in practice efficiency, clinical excellence, and patient satisfaction. By understanding selection criteria, implementing best practices, and maintaining your equipment properly, you’ll ensure years of reliable service and superior clinical outcomes.

Whether upgrading existing equipment or making your first purchase, remember that the right impression material dispenser can transform your practice’s impression procedures. Consider your specific needs, evaluate available options carefully, and don’t hesitate to request demonstrations before making your final decision.

Looking for Professional Dental Material Solutions?

🔬 Technical Consultation : Get expert guidance and product selection advice

📦 Sample Request : Receive free product samples for testing

💰 Quotation Service : Get the best pricing for bulk purchases

Contact Information

📞 Phone/WhatsApp : +86 180 1638 1172

🌐 Website : evendent.com

📧 Email : shevendent@gmail.com

Contact us now for expert technical support!